Applications

Surface temperature measurement

e.g.: Refrigerators, Freezers Air Conditioners

Features

High accuracy

Easy mounting

Good thermal coupling through Hexagonal Screw

Options

Alternative resistance ratings

Rated temperatures, tolerances and lead lengths

Encapsulation (Options available on request)

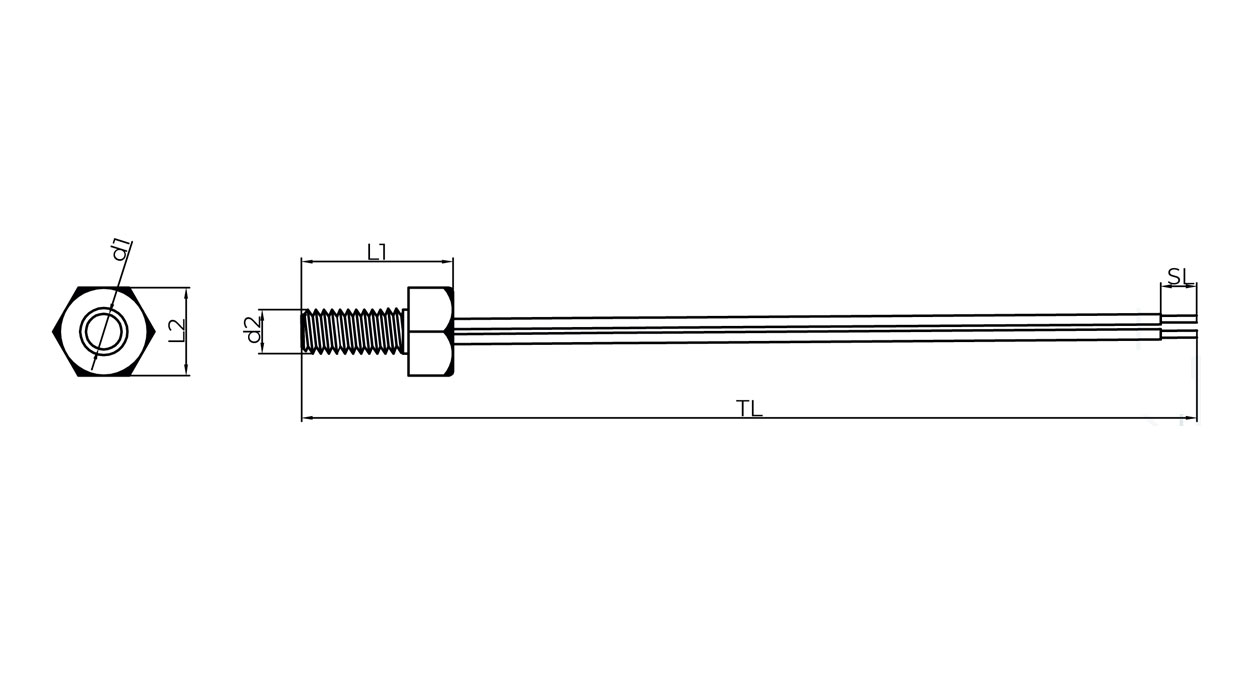

E43 – 10 mm Hexagonal Stud

E44 – 13 mm Hexagonal Stud

Type of Lead (Options available on request)

KH – 26 AWG Silver Plated Copper Wire

KK – 24 AWG Silver Plated Copper Wire

KF – 28 AWG Silver Plated Copper Wire

Lower Temperature : -40°C

Upper Temperature : 140°C

Max Permissible Power at 25°C : 60 mW

Resistance Tolerance (ΔR/RN ) : ±0.5%, ±1%, ±2%, ±5%

Rated Temperature (TN) : 25°C

Dissipation factor in air(δth) : approx 7 mW/K

Thermal cooling time constant in air (τc) : ≈ 130s

Beta Tolerance (Δβ/βN) : ±1%, ±2%, ±3%,

Heat capacity (Cth) : ≈ 900 mJ/K

Electrical Data

Resistance At 25°C (Ω) |

Beta Value (25/85) (K) |

2000 |

3540 |

2057 |

3540 |

2100 |

3900 |

2800 |

3977 |

3000 |

3977 |

4700 |

3977 |

5000 |

3977 |

10000 |

3977 |

Resistance At 25°C (Ω) | Beta Value (25/85) (K) |

20000 | 4000 |

30000 | 4050 |

47000 | 4100 |

49300 | 3960 |

50000 | 4100 |

100000 | 4400 |

170000 | 4250 |

*Customizations may be possible

Reliability Data

|

Test |

Standard | Test conditions |

ΔR25/R25 |

Remarks |

| Storage in dry heat |

IEC 60068-2- 2 |

Storage at upper category temperature T: 100 °C t: 1000 h |

< 2% | No visible damage |

| Storage in damp heat, steady state | IEC 60068-2-78 | Temperature of air: 40 °C Relative humidity of air: 93% Duration: 56 days | < 2% | No visible damage |

| Storage in coldness | Storage at lower category temperature T: -30 °C t: 1000 h | < 2% | No visible damage | |

| Rapid temperature cycling (in air) | IEC 60068-2-14 |

Lower test temperature: -30 °C Upper test temperature: 100 °C Time to change from lower to upper temperature: <30 s Number of cycles: 1000 Medium: oil |

< 2% | No visible damage |

| Vibration resistance | IEC 60068-2- 6 | Frequency range: 5 to 500 Hz Amplitude: 7.5 mm, 2 g Duration: 3 x 8 h | < 3% | No visible damage |

| Long-term stability (empirical value) | Temperature: 100 °C t: 10000 h | < 3% | No visible damage | |

| Voltage proof test | 1500 V AC, 1 s | No flashover | ||

| Insulation test |

The sensors are placed in a vessel containing metallic balls of 1 mm diameter (with total immersed head). The applied voltage is 100 V DC. |

Above 100 MΩ |

Part Number Identification

| PRODUCT SERIES CODE | RESISTANCE AT 25⁰C (10 X 10³ Ω) (10 KΩ) | RES.TOL | ENCAPSULATION | TYPE OF LEAD | WIRE GUAGE | TOTAL LENGTH 10 X 10² mm (1000 mm) | BETA (25/85) | CONNECTOR |

| STTS | 103 | R5 | E44 | K | H | 102 | 3977 | C5 |

STTS *** R# E%% @@ $$$ &&&& C!!

*** = Resistance Value at 25°C (e.g. 102- 1000Ω, 201 -200Ω, 103 – 10kΩ)

# = Resistance Tolerance (eg. R1 – ± 1%, R5 – ±5%)

%% = Encapsulation (eg. E44 – 13 mm Hexagonal Stud)

@@ = Type of Lead (eg. KH, K – PTFE-insulated Multistrand Copper Wire & H – 26 AWG)

$$$ = Total Length in mm (eg: 251 – 250mm Length, 401 – 400 mm Length)

&&&& = Beta Value (eg:3977K, 3830K)

!! = Connector (eg: C1 – JST XHP-2 PIN)