Applications

Temperature measurement

and compensation

Features

Wide resistance range

Cost – effective

Epoxy – coated thermistor disc

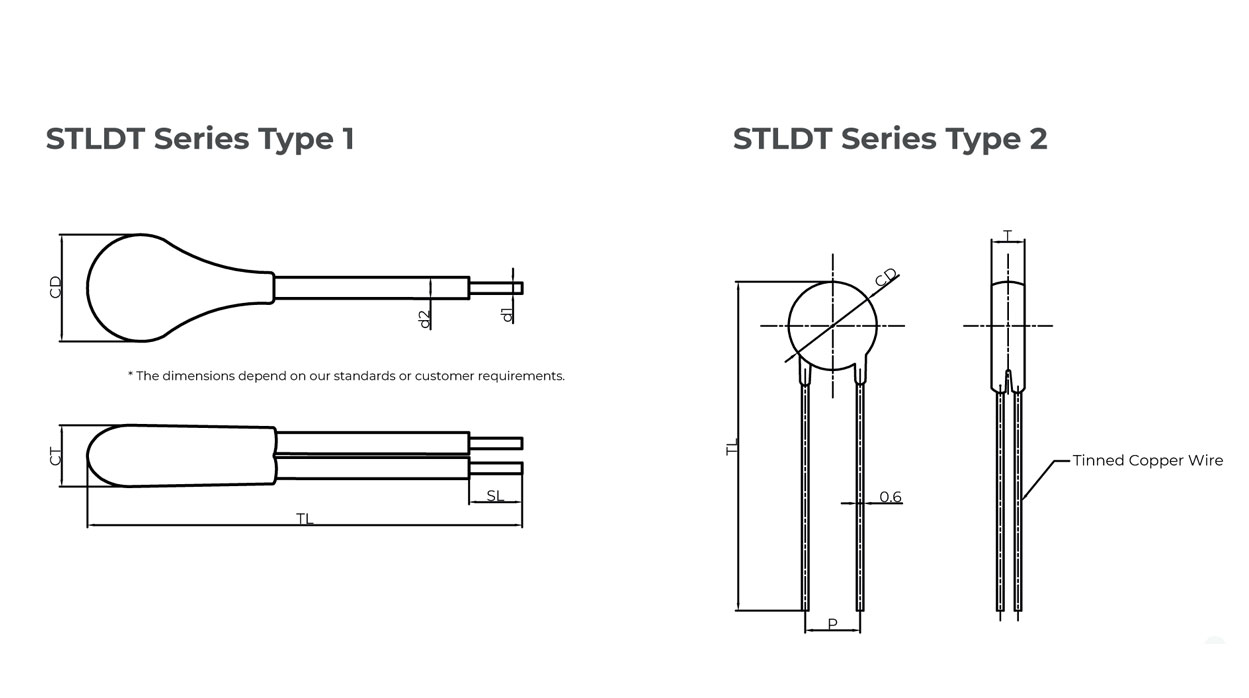

Tinned Copper lead

Options

Non-standard lead lengths

Alternative resistance ratings

Custom Specifications

Rated temperatures

and tolerances

Encapsulation (Options available on request)

E01 – Epoxy Powder Coated (Blue)

E02 – Epoxy Powder Coated (Black)

E70 – Epoxy Powder Coated (Golden Yellow)

Type of Lead (Options available on request)

GC – 30 AWG Single Strand Nickel Wire

KH – 26 AWG Silver Plated Copper Wire

KK – 24 AWG Silver Plated Copper Wire

GL – 23 AWG Single Strand Nickel Wire

HK – 24 AWG Single strand Copper Wire

Lower Temperature : 0°C

Upper Temperature : 120°C

Max Permissible Power at 25°C : 200 mW

Resistance Tolerance (ΔR/RN ) : ±1%, ±2%, ±5%

Rated Temperature (TN) : 25°C

Beta Tolerance (Δβ/βN) : ±1.5%, ±2%,

Dissipation factor in air(δth) : approx 1.5 mW/K

Thermal cooling time constant in air (τc) : 3-5s

Heat capacity (Cth) : approx 10-50 mJ/K

Thermal Response time : 10-15 s

*Max permissible current may depend upon thermistor diameter

Nominal Resistance, RN Specified at 25°C

Electrical Data

Resistance At 25°C |

Beta Value (25/85) |

| 470 | 3750 |

| 560 | 3750 |

| 680 | 3700 |

| 1000 | 3970 |

| 1200 | 3900 |

| 1700 | 3750 |

| 2100 | 3600 |

| 2200 | 3750 |

Resistance At 25°C (Ω) |

Beta Value (25/85) (K) |

2500 |

4000 |

3000 |

3977 |

10000 |

4000 |

20000 |

4300 |

30000 |

4000 |

68000 |

4250 |

Reliability Data

| Test | Standard | Test Conditions | Change in R25 (ΔR25/R25) | Remarks |

| Storage in dry heat | IEC 60068-2-2 | Storage at upper category temperature T: 100 °C t: 1000 h | < 3% | No visible damage |

| Storage in damp heat, steady state | IEC 60068 – 2- 78 | Temperature of air:40 °C Relative humidity of air: 93 % Duration: 56 days | < 1% | No visible damage |

| Rapid temperature cycling | IEC 60068 – 2- 14 | Lower test temperature: 0 °C Upper test temperature: 100 °C Number of cycles: 100 | < 2% | No visible damage |

| Long-term stability (empirical value) | Temperature: + 70°C Duration: 1000 h | < 3% | No visible damage | |

| ENDURANCE | Pmax : 200 mW t : 1000h | < 3% | No visible damage |

Part Number Identification

| PRODUCT SERIES CODE |

RESISTANCE AT 25⁰C (10 X 10² Ω) (1 KΩ) |

RES.TOL | ENCAPSULATION | TYPE OF LEAD | WIRE GUAGE |

TOTAL LENGTH 10 X 10² mm (1000 mm) |

BETA (25/85) |

| STLDT |

103 |

R5 |

E02 |

A |

L |

340 |

4000 |

STLDT *** R# E%% @@ $$$ &&&&

*** = Resistance Value at 25°C (e.g. 102- 1000Ω, 201 – 200Ω, 103 – 10kΩ)

# = Resistance Tolerance (eg. R1 – ± 1%, R5 – ±5%)

%% = Encapsulation (eg. E01 – Epoxy Powder Coated (Blue))

@@ = Type of Lead (eg. GC, G – Single strand Nickel Wire(Silver Plated) & C – 30 AWG)

$$$ = Total Length in mm (eg: 250 – 25mm Length, 401 – 400 mm Length)

&&&& = Beta Value (eg:3977K, 3830K)