Applications

Surface temperature measurement

(on housings and pipes Inverters, UPS, Air conditioners, Water heaters, Air warmers, Washing machines, Driers, Boilers etc)

Features

High accuracy

Easy mounting

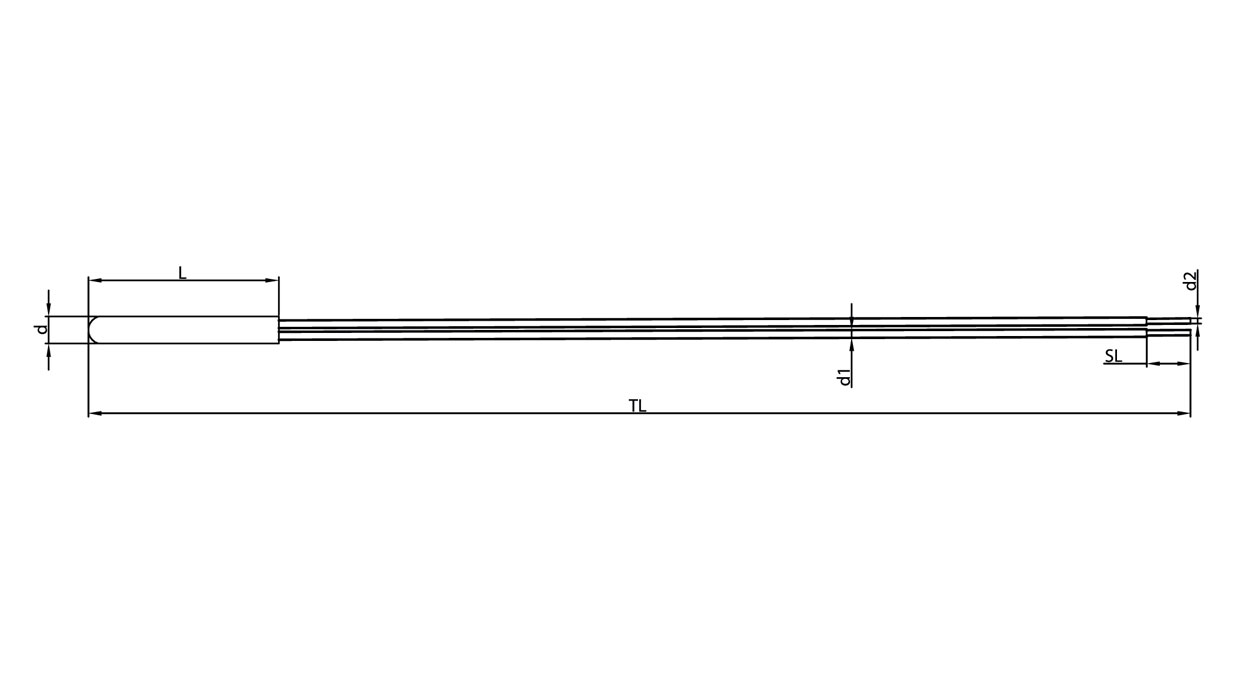

Thermistors encapsulated in

Copper Tube (5×25/6×25)

Good thermal coupling through metal tag

Black Twin Parallel Wire

Options

Alternative resistance ratings

Rated temperatures, tolerances and lead lengths

Encapsulation (Options available on request)

E10 – SS Tube 5×25 mm

E11 – SS Tube 6×25 mm

E18 – Copper Tube 6×25 mm

E23 – Grooved SS Tube 5×25 mm

E45 – Nickel Plated Brass Tube 5×25 mm

Type of Lead (Options available on request)

KH – 26 AWG Silver Plated Copper Wire

KK – 24 AWG Silver Plated Copper Wire

KF – 28 AWG Silver Plated Copper Wire

MN – 21 AWG PTFE Insulated 4-Core Shielded Wire

GC – 30 AWG Single Strand Nickel Wire

Lower Temperature : -40°C

Upper Temperature : 140°C

Max Permissible Power at 25°C : 60 mW

Resistance Tolerance (ΔR/RN ) : ±0.5%, ±1%, ±2%, ±5%

Rated Temperature (TN) : 25°C

Dissipation factor in air(δth) : approx 130s

Thermal cooling time constant in air (τc) : ≈ 20s

Beta Tolerance (Δβ/βN) : ±1%, ±2%, ±3%,

Heat capacity (Cth) : ≈ 900 mJ/K

Electrical Data

Resistance At 25°C (Ω) |

Beta Value (25/85) (K) |

2000 |

3540 |

2057 |

3540 |

2100 |

3900 |

2800 |

3977 |

3000 |

3977 |

4700 |

3977 |

5000 |

3977 |

| 10000 | 3977 |

Resistance At 25°C (Ω) |

Beta Value (25/85) (K) |

20000 |

4000 |

30000 |

4050 |

47000 |

4100 |

49300 |

3960 |

50000 |

4100 |

100000 |

4400 |

170000 |

4250 |

Reliability Data

|

Test |

Standard | Test conditions |

ΔR25/R25 |

Remarks |

| Storage in dry heat |

IEC 60068-2- 2 |

Storage at upper category temperature T: 100 °C t: 1000 h |

< 2% | No visible damage |

| Storage in damp heat, steady state | IEC 60068-2-78 | Temperature of air: 40 °C Relative humidity of air: 93% Duration: 56 days | < 2% | No visible damage |

| Storage in coldness | Storage at lower category temperature T: -30 °C t: 1000 h | < 2% | No visible damage | |

| Rapid temperature cycling (in air) | IEC 60068-2-14 |

Lower test temperature: -30 °C Upper test temperature: 100 °C Time to change from lower to upper temperature: <30 s Number of cycles: 1000 Medium: oil |

< 2% | No visible damage |

| Vibration resistance | IEC 60068-2-6 | Frequency range: 5 to 500 Hz Amplitude: 7.5 mm, 2 g Duration: 3 x 8 h | < 3% | No visible damage |

| Long-term stability (empirical value) | Temperature: 100 °C t: 10000 h | < 3% | No visible damage | |

| Voltage proof test | 1500 V AC, 1 s | No flashover | ||

| Insulation test |

The sensors are placed in a vessel containing metallic balls of 1 mm diameter (with total immersed head). The applied voltage is 100 V DC. |

Above 100 MΩ |

Part Number Identification

| PRODUCT SERIES CODE | RESISTANCE AT 25⁰C (10 X 10³ Ω) (10 KΩ) | RES.TOL | ENCAPSULATION | TYPE OF LEAD | WIRE GUAGE | TOTAL LENGTH 10 X 10² mm (1000 mm) | BETA (25/85) | CONNECTOR |

| STTS | 103 | R5 | E10 | K | H | 102 | 3977 | C5 |

STTS *** R# E%% @@ $$$ &&&& C!!

*** = Resistance Value at 25°C (e.g. 102- 1000Ω, 201 -200Ω, 103 – 10kΩ)

# = Resistance Tolerance (eg. R1 – ± 1%, R5 – ±5%)

%% = Encapsulation (eg. E01 – Blue Powder Coating)

@@ = Type of Lead (eg. KH, K – PTFE-insulated Multistrand Copper Wire & H – 26 AWG)

$$$ = Total Length in mm (eg: 251 – 250mm Length, 401 – 400 mm Length)

&&&& = Beta Value (eg:3977K, 3830K)

!! = Connector (eg: C1 – JST XHP-2 PIN)